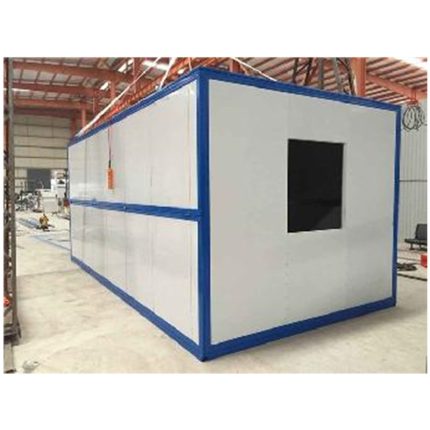

The advantage of dingrong folding container house is as follows

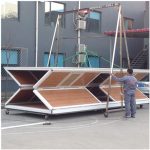

1.install one house in 10 minutes

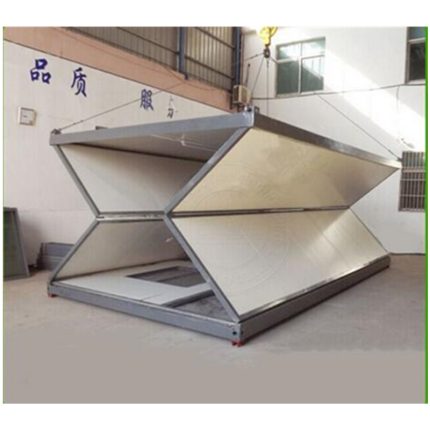

2.expand size:W2.48M*L5.8M*H2.5M(interior size W2.295*L5.6*H2.3m) folded size:W2.48*L5.8*H0.49M

3.one 40HC container can load 8 units

4.with insulation

5.galvanized frame+two layers painting,hard to get rusted

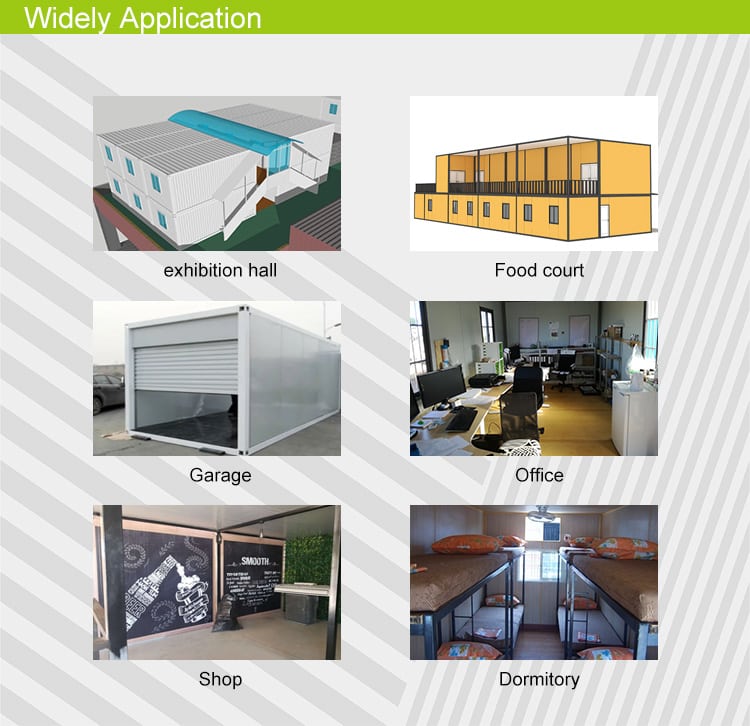

6.can be stacked two levels,and add veranda,canopy,railing,stair

7.one set frame around 650kg,one set house is around 1400kg

2. Technical Specs:

| Item | Details |

| External Size | L5800mm*W2480mm*H2470mm |

| Main frame | Galvanized steel+powder coating |

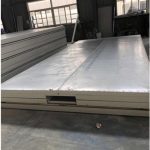

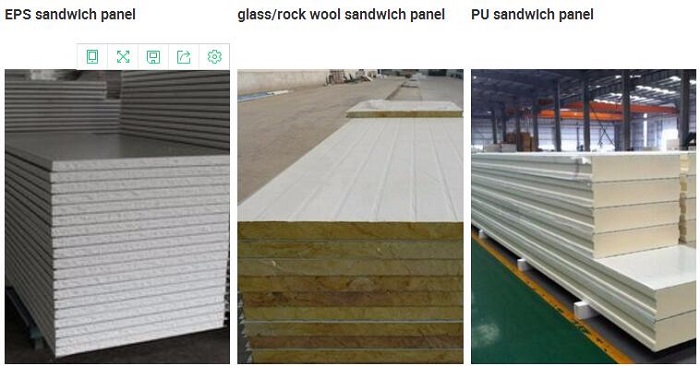

| Wall panel | Color steel sandwich panels Material options:EPS/Glass wool/ Rock wool/ (thickness of panel can be 50/75/100mm or custom) |

| Roof panel | Steel sheet with 75mm glass wool insulation |

| Floor | Cement fiber board/MGO board+PVC floor(optional) |

| Window | Sliding window |

| Door | Steel security door |

| Loading | 10 units for 40’HQ |

3. Container Engineering Report

1.1 General Technical Condition

1)The structure can prevent the 8 magnitude earthquake.

2)The design of seismic grouping is the first group, the site characteristic cycle is considered 0.45s, the construction site category is considered by Class III, and the damping ratio of steel structure is 0.05. The maximum αmax of the horizontal earthquake influence coefficient is 0.04, which is calculated by 5 years.

3) Structural safety level is grade 2. The coefficient of importance is 1.0.

4) Conner fitting elevation plus or minus zero.

1.2 Materials

Normally,steel beams, steel columns, purlin are all used Q235B cold bending galvanized light steel.

strength of steel:f=215N/m2

1.3 Loading Combination

1.Calculation of floor Loading

(1)Bottom Flooring

Structure Weight 0.4 kN/m2

Dead Load Value 0.4 kN/m2

Live Load Value 3.0 kN/m2

(2)Roof board

Structure Weight 0.3 kN/m2

Dead Load Value 0.3 kN/m2

Live Load Value 0.5 kN/m2

2.Calculation of Wind loading

According to the 15 Design durable years, the basic wind pressure of wind loading is W0=0.3KN/m2

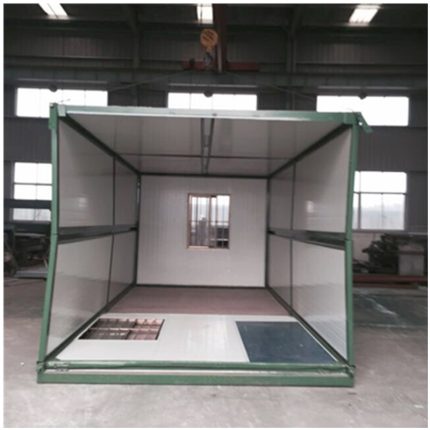

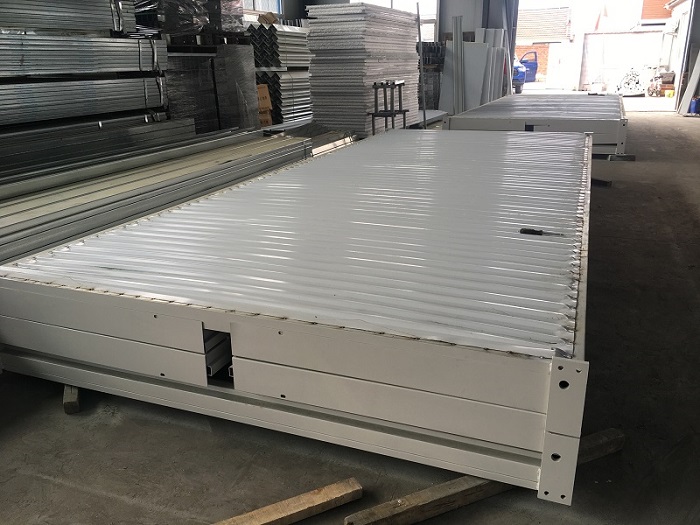

4.Container frame

top :170*2.0mm thickness frame+two layers paint

bottom:270*2.5mm thickness frame+two layers paint

column:155*2mm thickness frame+two layers paint

5.wall&roof of foldable container house

50mm rock wool sandwich panel is standard material for wall

optional thickness 75mm,100mm.optional insulation glass wool,EPS,polyuranthane

6.floor of prefab 20ft foldable folding container house

MGO board works as the bottom floor tile

and PVC tile,carpet or wood floor and be added on top of MGO board

7.roof and ceiling of prefab 20ft foldable folding container house

steel plate+50mm glass wool insulation+steel ceiling

8.window and door of folding container house

Packing&shipping

the foldable container house can be folded and unfolded many times,so we fold it for shipping

1*40HC shipping container can load 10 units foldable house

Successful container house projects

we have done 5000+ successful container homes projects over 50 countries including australia,USA,germany,france,brazil etc.we provide one stop solution for your modular container house projects including design,production,delivery,installation etc.

FAQ

1. What’s your delivery time?

Normal order delivery time is 7-30 days after receive deposit.

Big order delivery time should confirm with order management dept.

2. How do you guarantee the quality of the products?

Quality first, 100% Strict quality checking before delivery.

3. How can I get the quotation of the project ?

If you have drawing, we can offer quotation accordingly.

If you don’t have design, we will design some drawings for your confirmation, and then offer quotation.

4. Can you help me to purchase other things like furniture or appliance?

Yes. We provide one stop shopping arrangement for housing project.We can offer you the final solution of the house. Please send me your detail request for other facilities.

5. How to install /assemble the house?

Usually it is very easy and fast to assemble the house and there we will supply you the detailed assembling video and drawing with panel number.

6. Do you provide on-site installation service?

For big projects,we can provide installation services.The buyer should pay for the visa, two-way-air ticket, food, accomodation, transportation and 150USD/day per person salary for the installation engineer.